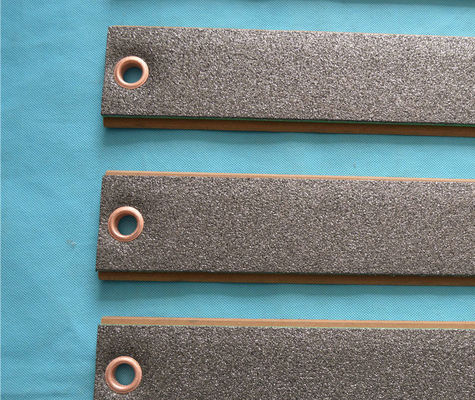

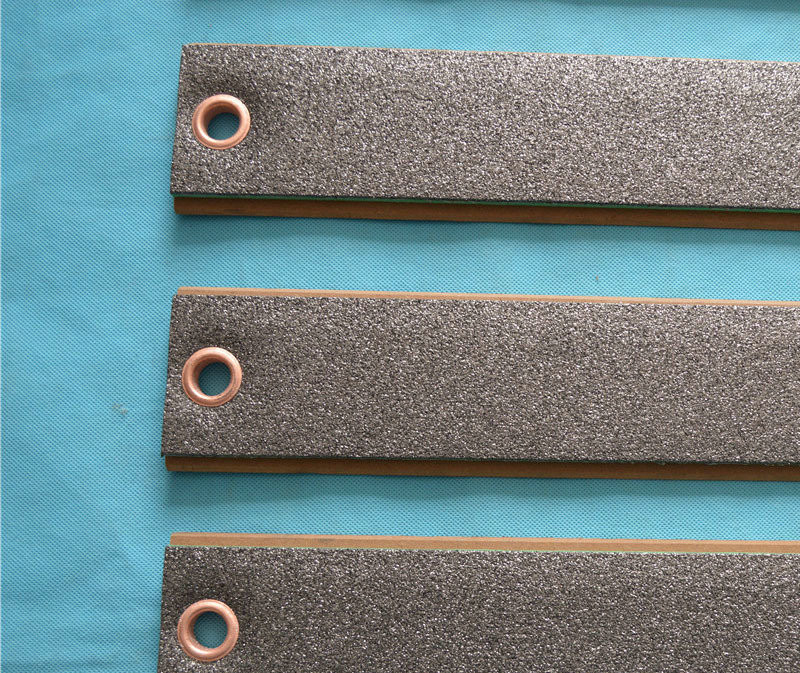

83*1450 Fine Sanding Grinding Polishing Slide Pad Spring Insert

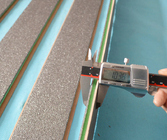

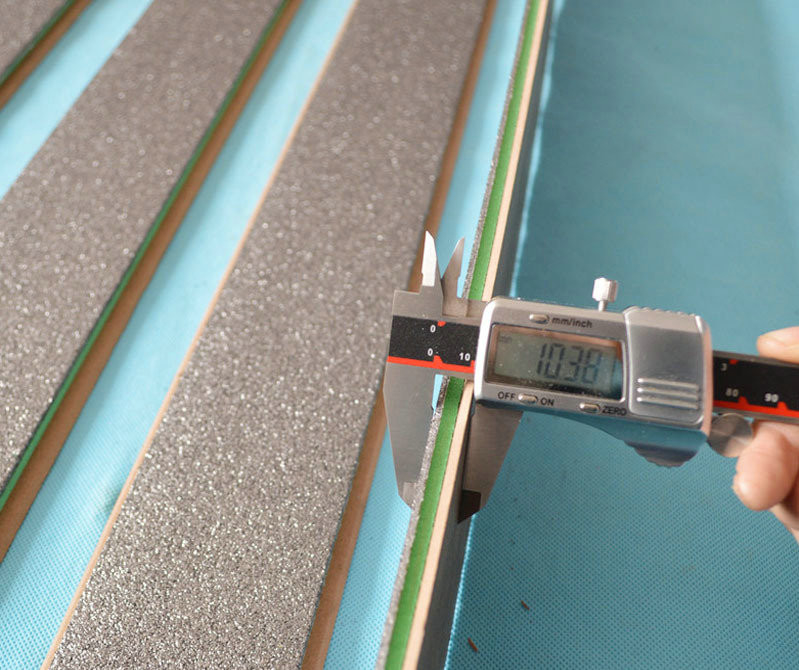

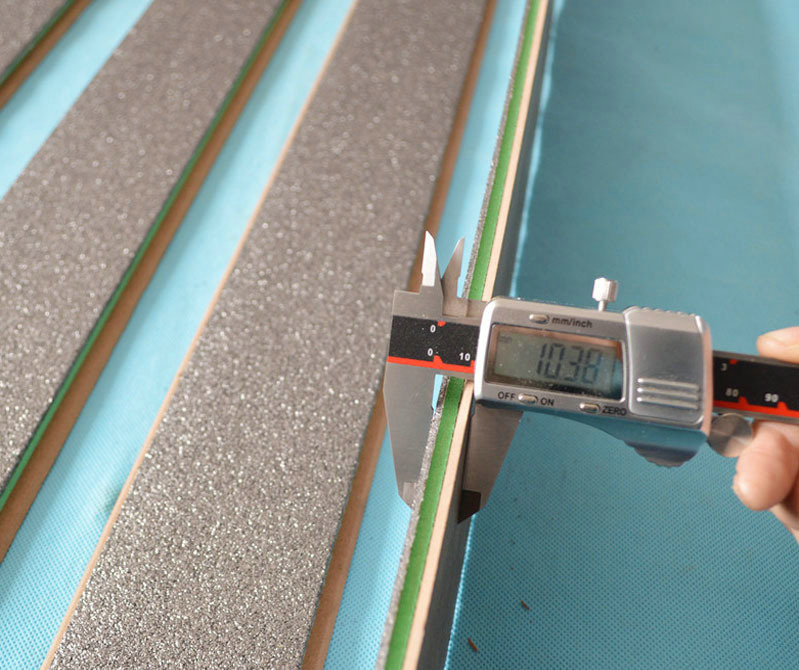

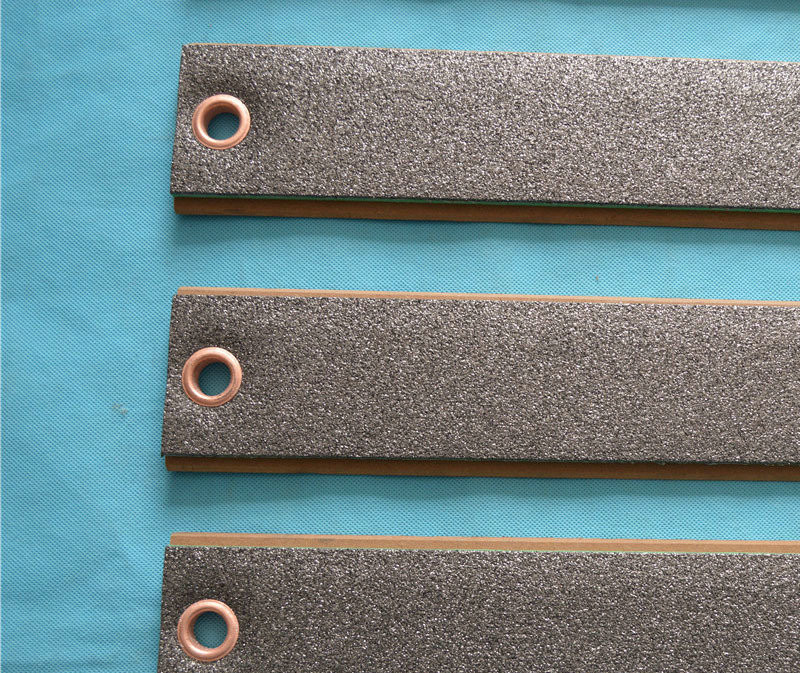

Graphite cloth press grinding plate (also known as quick loading press grinding pad), the graphite cloth and elastic liner are bonded in turn on the long strip of the supporting plate, the two sides of the supporting plate is provided with a pinch, at one end of the supporting plate is provided with a fixing hole. In this way, the grinding plate can be quickly installed through the indent of the supporting plate and the grinding assembly of the sander, and the grinding plate can not be shifted through the fixed hole locking. The standardized production of press grinding board makes the replacement of graphite cloth and elastic liner simple and fast, and forms a unified standard in terms of thickness, density and hardness, and customers are more accurate in the selection of products.

Normal size: 83*1450mm, 83*2750mm, 83*2980mm, 70*1480mm, 70*2980mm

Other sizes can be customized.

1. Grit: 24#, 30#, 36#, 40#, 50#, 60#, 80#, 100#, 120#, 150#, 180#, 220#, 240#, 280#, 320#

2. Millstone raw materials: brown corundum, zirconium corundum, silicon carbide

3. Base material: all polyester cloth

4. Dimensions: width 100mm-3200mm

5. Length 200mm-4000mm

Advantage

1. Long Life

2. High Efficiency

3. Will not damage surface

4. Excellent Edge Durability

5. Consistent Finish

6. The specification and sizes can be made according to your requirements

|

Backing

|

Y-polyester cloth, G-paper, Combination (cotton/paper)

|

|

Bonding

|

Synthetic resin

|

|

Grain

|

Silicon carbide, Aluminium oxide

|

|

Available grits

|

P16, P24, P36, P40, P50, P60, P80, P100, P120, P150, P180

|

|

Coating

|

Dense

|

|

Application area

|

Particle board, MDF, HDF, OSB, LSB, HPL, Wood, Cement board, Gypsum board, Metal

|

Strong joint

Joint processing using automation equipment excellent production technology, German glue joint firm firm, long service life

Fine cloth base

High strength polyester cloth base, with graphite coating, improve the pass rate of sand belt and reduce power consumption

The abrasive is of excellent quality

Selection of silicon carbide abrasive, cutting force, good self-sharpening, strong toughness, not easy to remove sand, not easy to plug

I. Advantages of our sand belt:

1, high performance, high quality products, can play excellent performance under extremely harsh working conditions;

2. Durable life, the service life of our belt is better than that of similar products;

3. High cost performance, greatly reducing the long-term investment cost of customers;

4. Perfect pre-sales technical service and after-sales service.

Our belt with its excellent wear resistance and stable quality, won the recognition of a wide range of customers at home and abroad.

Our belt cloth contains graphite, which plays the role of lubrication, improves the passing rate of the belt, reduces the friction on the equipment, and extends the life of the equipment. This is not only very good for your equipment, but also can ensure the effect of the board. In addition, because the graphite conducts electricity, the cloth base of our product also has the effect of antistatic. At the same time, the sand surface also contains antistatic agents, which can bring out the electrostatic conductivity and prevent the dust blockage on the sand surface, so as to improve the wear resistance and durability of the sand belt.

The joints of our belt are all made of German and Italian equipment, German technology, and pure imported German glue, so that you can get excellent sanding effect on the board. We are willing to provide your company with the most reasonable sanding program, so that your company can improve the production efficiency at the same time, get the maximum economic benefits.

FOR MORE INFORMATION, DO NOT HESITATE TO CONTACT WITH US.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!