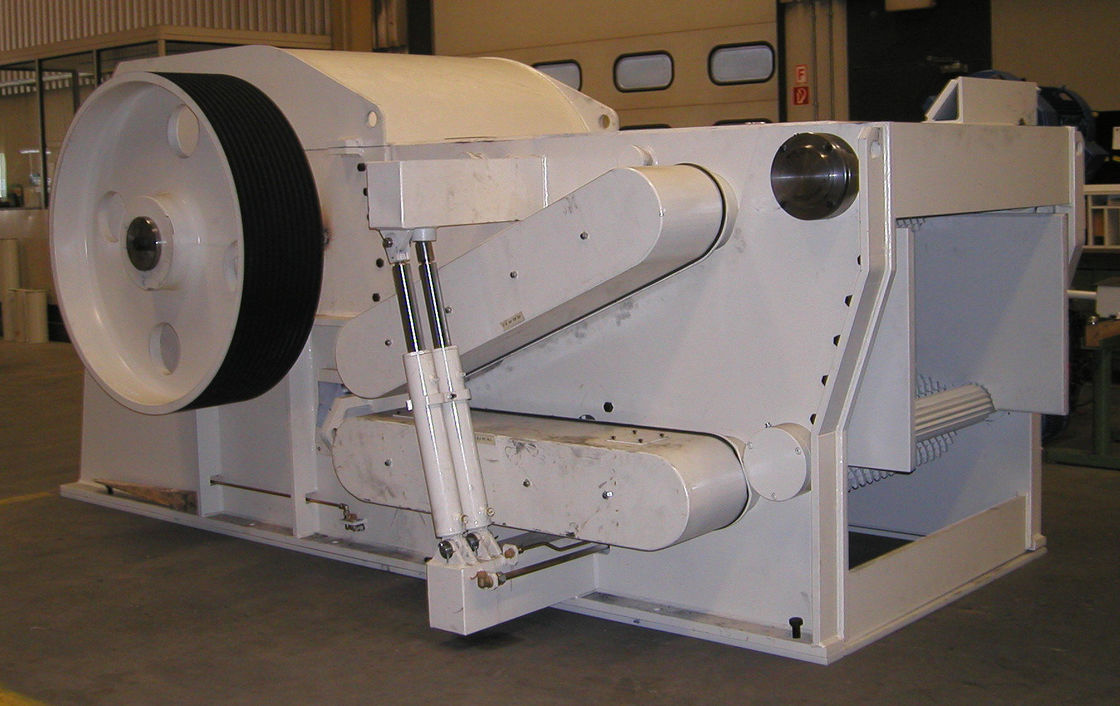

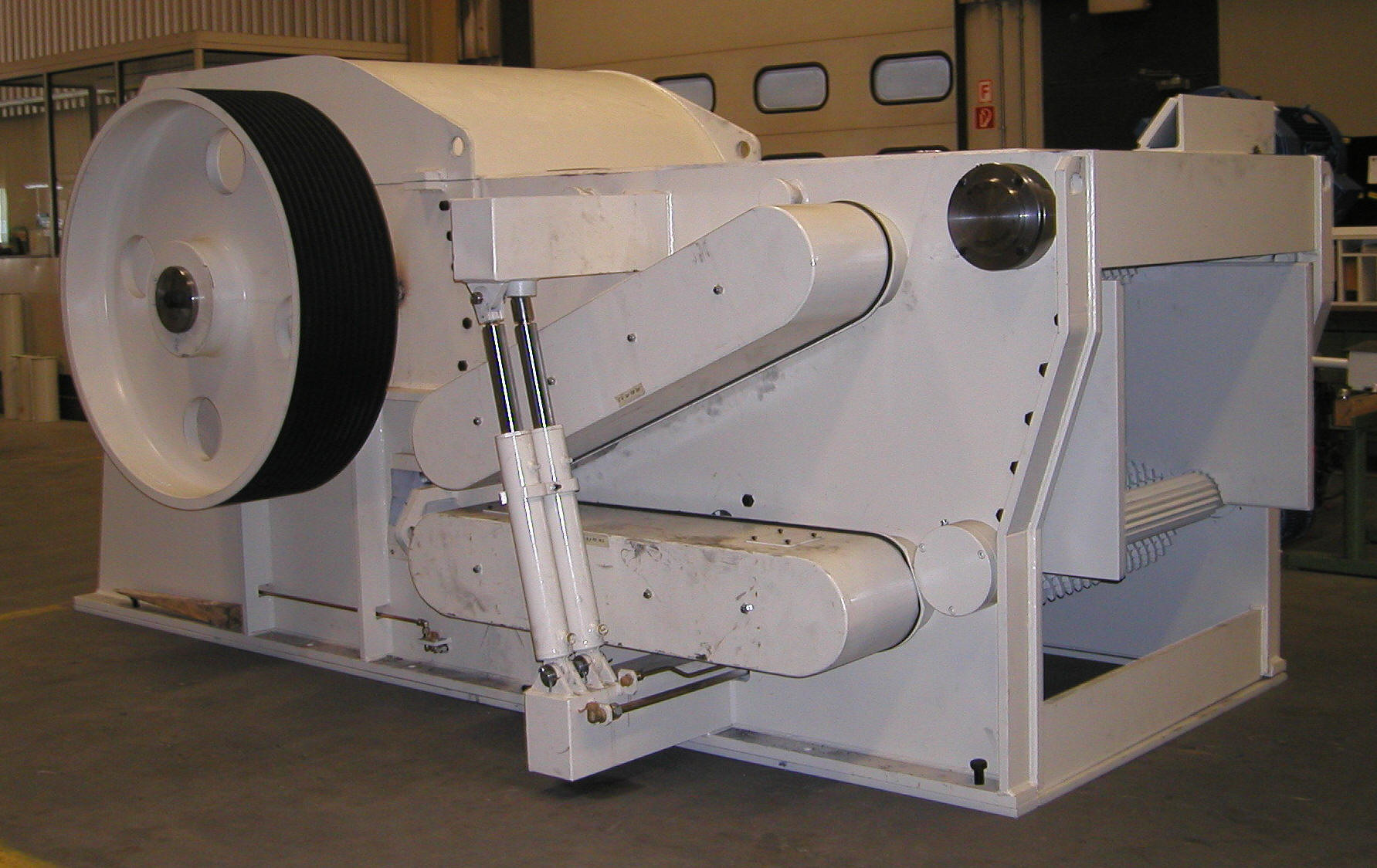

Effective Drum Chipper With Belt Conveyor For PB / MDF / OSB

1. Drum chipper is an ideal equipment for producing good chips, and it's widely used in paper factories, particle board plants, MDF plants, biomass power plants and etc. It can cut materials of certain diameters into chips, such as wood logs, branches, bark, veneers, bamboo, various stalks/straws and etc, and the output sizes are even and uniform. On the other hand, drum chipper has advanced and strong structure, which enables a stable quality and multi-function and easy maintainance.

2. The chipper consists of machine frame, knife rotor assembly, upper feed rollers, lower feed rollers, belt conveyor unit, hydraulic and electrical system,with the strong structure, easily operation for chopping the wood,bamboo and other non-fiber stems.

3. This series of drum chippers are structurally compact, simple to operate, high throughput, wide adaptability of raw materials, produces high chips quality, reliable and e, easy to maintain, and are the most advanced chippers currently available in China.

4.This series of drum chippers are suitable for the range of 3-130 cubic meters/hour. The standard sizes available are convenient for customers to select in accordance with the production requirement.

Introduction

Drum chipper is the traditional product of our company. It is widely used by domestic and oversea customers because of its good performance, top quality and other advantages. The drum chipper is the special equipment for producing perfect chips. It is used in paper plant, particle board plant, fiber-board plant and chips bases. By which, logs and small wood are cut into high quality chips with even length and uniform chip thickness, it is also suitable for the chipping of branches and twigs, planks and etc. The chip length is different in accordance with the requirement of paper plant, particle board and fiber-board industries, so in order to meet this need, our company improve different kind of drum chippers recently, and the new type machine has more advantages. All the features show that it is an ideal equipment for chip production which can be uses all over the world.

Main compose of drum chipper

-

The machine base is a welding structure with high strength steel plate serving as a support of the whole machine.

-

The knives (2,3 or 4) are installed to the roller via clamping plate by special knife bolts. The upper feed rollers assembly, with the help of hydraulic system, can float up and down over the material to be cut within certain range, according to the thickness of the material. Wood chips are discharged from the bottom of the machine after passing through screen holes, oversized chips will be re-chipped in the machine.

-

Hydraulic system: the oil pump supplies the cylinder with pressure oil, and open the drum cover for easy knife change; and lift the upper feed roller to facilitate the adjustment of the clearance between rotor knives and bed knives, and ease the changing of comb plate.

Main characteristics of drum chipper

-

Adopted to a variety of raw materials: Our drum chipper has a wide range of adoptability in cutting wood and non-wood materials

-

Strict quality control in entire process, which start from design, manufacture to after sale service: Decades of experience to manufacture chipper, and strict industry standard. Selected raw materials, Strict quality control to the outsource fittings. Electric elements, hydraulic element are high quality brands at home and abroad. Large precise equipment ensures us manufacturing quality chipper.

-

Lower operating cost to the users: The design ensures the chipper can be faster and easier to maintenance, reduce operating cost.

|

Model

Specifications

|

BX216

|

BX218

|

BX218D

|

BX2110

|

BX2113A

|

BX2113B

|

BX2113C

|

BX2116

|

|

(mm)

Rotor diameter

|

650

|

800

|

800

|

1000

|

1300

|

1300

|

1300

|

1600

|

|

Number of flying knives (pc)

|

2

|

2

|

2

|

2×2

|

3

|

3×2

|

4×2

|

4×2

|

|

(mm)

Feed opening

|

180×500

|

225×680

|

240×780

|

330×1050

|

400×700

|

400×1050

|

400×1250

|

600×1250

|

|

(rpm)

Knife rotor speed

|

590

|

650

|

650

|

550

|

420

|

442

|

378/340

|

350

|

|

(m/min)

Feed speed

|

37.2

|

37

|

38

|

33

|

38

|

43

|

36/42

|

42

|

|

Processing raw material max diameter (mm)

|

120

|

160

|

160

|

190

|

230

|

240

|

250

|

310

|

|

(mm)

Wood Chips length

|

30

|

30

|

30

|

30

|

30

|

32

|

24/32

|

30

|

|

(m3/h)

Capacity

|

10

|

15-20

|

38

|

75

|

60-70

|

100

|

130

|

180

|

|

(KW)

Main motor power

|

55

|

110

|

132

|

220

|

250

|

315

|

450

|

710 (10kV)

|

|

(KW)

Feed roller motor power

|

2×3

|

2×4

|

2×5.5

|

2×7.5

|

2×7.5

|

2×11

|

2×15

|

2×18.5

|

|

(KW)

Oil pump motor power

|

|

|

0.37

|

3

|

3

|

3

|

3

|

4

|

|

(kg)

Weight

|

4070

|

7000

|

8000

|

12500

|

13840

|

16700

|

18000

|

32000

|

|

Overall dimensions

(L×W×H)

|

4348×2056

×1258

|

4670×2150

×1500

|

4670×2250

×1515

|

2850×2799

×1497

|

3670×2517

×2050

|

3485×2350×

1828

|

5484×5400

×1862

|

4360×3150×

2200

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!