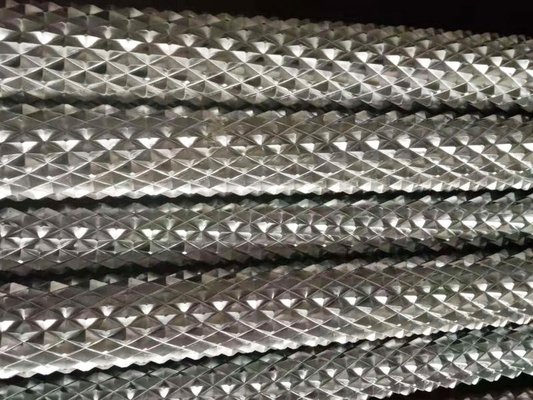

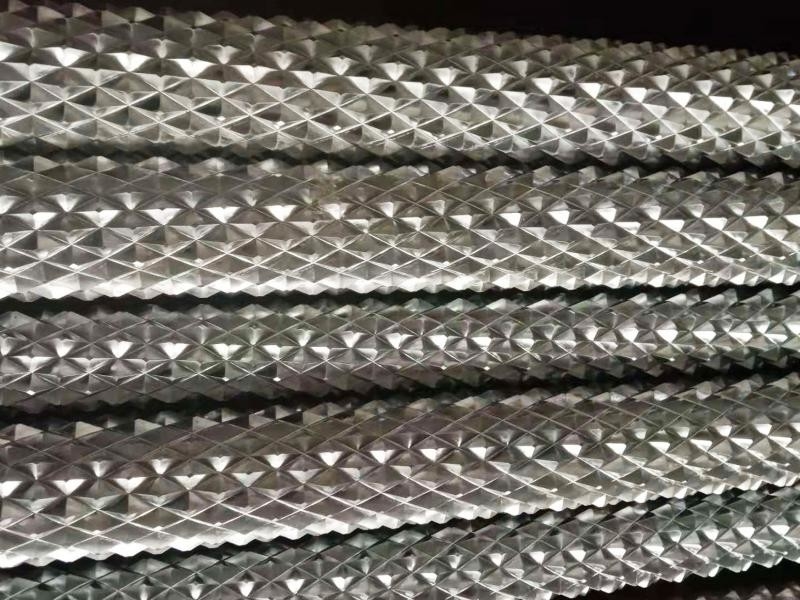

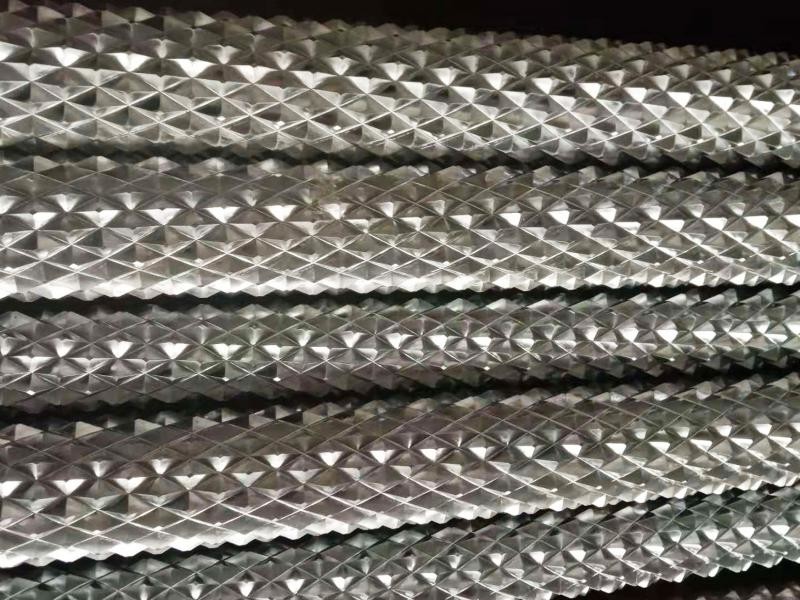

Diamond Roller Forming Machine Particle Board Machine Line

The diamond roller forming machine is an important device in the production of the particleboard. The diamond roller forming machine directly affects the quality of the particle board production materials. Let me introduce to you how to ensure accuracy of the diamond roller forming machine. The content is as follows:

1. Diamond roller material and thermal treatment process must ensure the effects of diamond rollers. Diamond rollers are used for heat treatment with high -quality alloy steel materials to ensure the hardness and rigidity of the material of the material, and reduce the processing of diamond rollers.

2. Machining accuracy of diamond roller spiral line. Generally, the forming depends on the groove of the diamond roller, not the gap between the diamond roller. The grooves of the diamond roller are small, small, and high accuracy. Diamond roller shop installed machines use several special CNC screw machine tool production lines, machine tools use special heavy load beds for rails, Siemens CNC systems, effectively control the diamond roller spiral accuracy of 0.001 degrees, diamond roller straight lines 0.015mm, and the production of diamond rollers depends on The equipment guarantees the depth of the left and right spiral grooves, and the diamond surface is smooth.

3. Precision grinding bed grinding guarantees high precision. Diamond roller precision imported grinding beds to ensure the size and accuracy of diamond rollers and bearings.

4. Precision detection methods. The diamond roller is completed and the key size accuracy is detected by a large three -coordinate detection.

5. Diamond roller surface treatment. The outer round and groove surface of the diamond roller spray a certain thickness alloy plating on the surface, which has high hardness, abrasion resistance, and corrosion resistance.

Diamond roller is the core component of the diamond roller forming machine, and it is a faster wear, so it needs to be adjusted faster and faster.

The quality of the diamond roller and the operation directly determine the flatness, uniformity, and grading effect of the blank. The company specializes in the production of various types of diamond roller forming machines and its accessories.

Among them, the diamond roller uses Finnish drawings, which has been upgraded many times in combination with domestic and foreign technology to develop a diamond roller forming machine with its own characteristics.

Because the forming machine manufacturers currently use in the market will also have different diamond rolling accessories, the company can support the corresponding diamond roller for various models of the pavement machine.

Mainly diamond roller processing parameters:

Common length of diamond rollers: 1320mm 1950mm and customized according to customer needs drawing

Common diamond roller diameter: 60mm 70mm 80mm 90mm according to customer needs

Dead depth: Made according to drawings and equipment supporting facilities

The company's professional processing of various models of diamond rollers has successively supported multiple machinery factories and board factories, with high quality and competitive price. The company's quality assurance, wear resistance and deformation of the after -sales diamond roller, will be replaced for free for all quality problems.

What is PB ?

Particle board – also known as particleboard, low-density fibreboard (LDF), and chipboard – is an engineered wood product manufactured from wood chips, sawmill shavings, or even sawdust, and a synthetic resin or other suitable binder, which is pressed and extruded. Oriented strand board, also known as flakeboard, waferboard, or chipboard, is similar but uses machined wood flakes offering more strength. All of these are composite materials that belong to the spectrum of fiberboard products.

Characteristics

Particle board is cheaper, denser and more uniform than conventional wood and plywood and is substituted for them when cost is more important than strength and appearance. Particleboard can be made more appealing by painting or the use of wood veneers on visible surfaces. Though it is more dense than conventional wood, it is the lightest and weakest type of fiberboard, except for insulation board. Medium-density fibreboard and hardboard, also called high-density fiberboard, are stronger and denser than particleboard. Different grades of particleboard have different densities, with higher density connoting greater strength and greater resistance to failure of screw fasteners.

A significant disadvantage of particleboard is its susceptibility to expansion and discoloration from moisture absorption, particularly when it is not covered with paint or another sealer. Therefore, it is rarely used outdoors or in places where there are high levels of moisture, except in bathrooms, kitchens and laundries, where it is commonly used as an underlayment shielded beneath a moisture resistant continuous sheet of vinyl flooring.

In dry environments, veneered particleboard is preferred over veneered plywood because of its stability, lower cost, and convenience.

Manufacturing

Particleboard or chipboard is manufactured by mixing wood particles or flakes together with a resin and forming the mixture into a sheet. The raw material is fed into a disc chipper with between four and sixteen radially arranged blades. The chips from disk chippers are more uniform in shape and size than from other types of wood chippers. The particles are then dried, and any oversized or undersized particles are screened out.

Resin is then sprayed as a fine mist onto the particles. Several types of resins are used. Amino-formaldehyde based resins are the best performing based on cost and ease of use. Urea Melamine resins offer water resistance with more Melamine offering higher resistance. It is typically used in external applications, with the coloured resin darkening the panel. To further enhance the panel properties, resorcinol resins can be mixed with phenolic resins, but that is more often used with marine plywood applications.

Panel production involves other chemicals including wax, dyes, wetting agents and release agents, to aid processing or make the final product water resistant, fireproof, or insect proof.

After the particles pass through a mist of resin sufficient to coat all surfaces, they are layered into a continuous carpet. This 'carpet' is then separated into discrete, rectangular 'blankets' which will be compacted in a cold press. A scale weighs the flakes, and they are distributed by rotating rakes. In graded-density particleboard, the flakes are spread by an air jet that throws finer particles further than coarse ones. Two such jets, reversed, allow the particles to build up from fine to coarse and back to fine.

The formed sheets are cold-compressed to reduce thickness and make them easier to transport. Later, they are compressed again, under pressures between 2 and 3 megapascals (290 and 440 psi) and temperatures between 140 and 220 °C (284 and 428 °F) to set and harden the glue. The entire process is controlled to ensure the correct size, density and consistency of the board.

The boards are then cooled, trimmed and sanded. They can then be sold as raw board or surface improved through the addition of a wood veneer or laminate surface.

|

ITEM

|

INDEX

|

|

Raw Material

|

Pine,

Poplar,

Fir

|

|

Glue Type

|

MDI,

PF,

UF

|

|

Hot Press

|

Multi-opening Press,

Continuous Press

(4 ft, 8 ft, 12 ft)

|

|

Design capacity

|

50000,

150000,

250000 Cubic Meters

|

If you are interested, do not hesitate to contact me.

REGARDS!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!