FSC E0 E1 2440*1220 Oriented Strand Board OSB LSB Flakeboard Chipboard

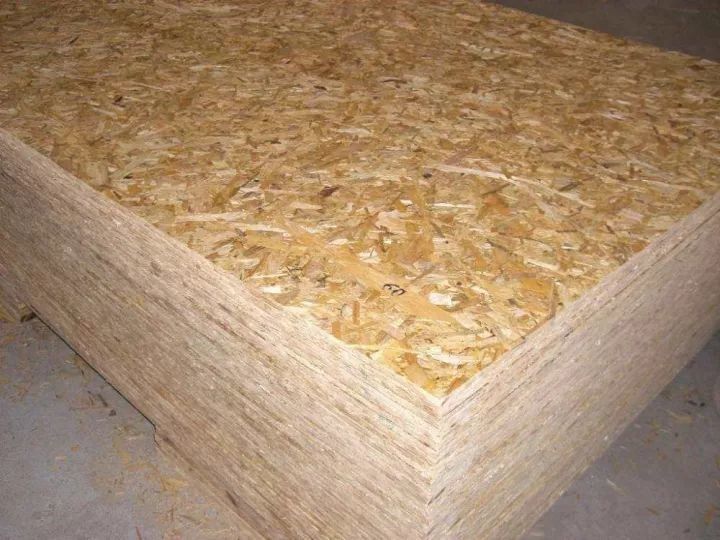

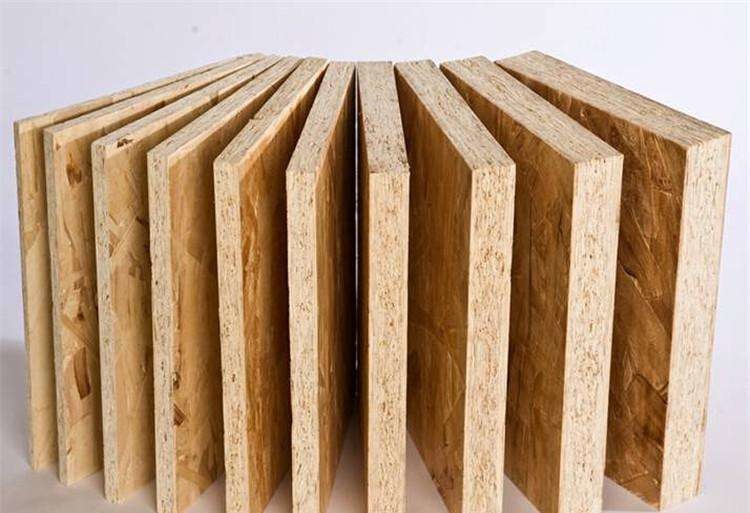

Oriented strand board (OSB), also known as flakeboard, is a type of engineered lumber similar to particle board, formed by adding adhesives and then compressing layers of wood strands (flakes) in specific orientations. It was invented in California in 1963. OSB may have a rough and variegated surface with the individual strips of around 2.5 cm × 15 cm (1.0 by 5.9 inches), lying unevenly across each other and comes in a variety of types and thicknesses.

OSB is a material with favorable mechanical properties that make it particularly suitable for load-bearing applications in construction. It is now more popular than plywood, commanding 66% of the structural panel market. The most common uses are as sheathing in walls, flooring, and roof decking. For exterior wall applications, panels are available with a radiant-barrier layer pre-laminated to one side; this eases installation and increases energy performance of the building envelope. OSB also sees some use in furniture production.

Adjustments to the manufacturing process can impart differences in thickness, panel size, strength, and rigidity. OSB panels have no internal gaps or voids, and are water-resistant, although they do require additional membranes to achieve impermeability to water and are not recommended for exterior use. The finished product has properties similar to plywood, but is uniform and cheaper. When tested to failure, OSB has a greater load-bearing capacity than milled wood panels. It has replaced plywood in many environments, especially the North American structural panel market. Unfortunately, its use as sheathing has contributed to the leaky condo crisis, as it is less able to breathe and release moisture than plywood.

Oriented standard board ,also known as oriented chipboard ,OSB OSB floor base material is a new kind of wooden board product made of raw wood by peeling and hot pressing The raw material of production is pine footpath material ,branch material and edge

Main uses:

It can be perfectly used universally and decoratively: as a building panel in shell construction, as a constructive element in wood construction, as wall or roof panelling in interior design or as a subfloor panel in the flooring area as well as the packaging industry.

Mainly used for the interior wall ,heat insulation board ,ceiling ,common furniture and interior decoration ,wooden door and sofa keel .

OSB/1- The exterior wall ,roof panel ,floor panel and waterproof panel of the wooden house

OSB/2 - Load-bearing boards for use in dry conditions

OSB/3 - Load-bearing boards for use in humid conditions

OSB/4 - Heavy-duty load-bearing boards for use in humid conditions

|

ITEM

|

INDEX

|

|

Raw Material

|

Pine,

Poplar,

Fir

|

|

Glue Type

|

MDI,

PF,

UF

|

|

Hot Press

|

Multi-opening Press,

Continuous Press

(4 ft, 8 ft, 12 ft)

|

|

Design capacity

|

50000,

150000,

250000 Cubic Meters

|

If you are interested, do not hesitate to contact me.

REGARDS!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!