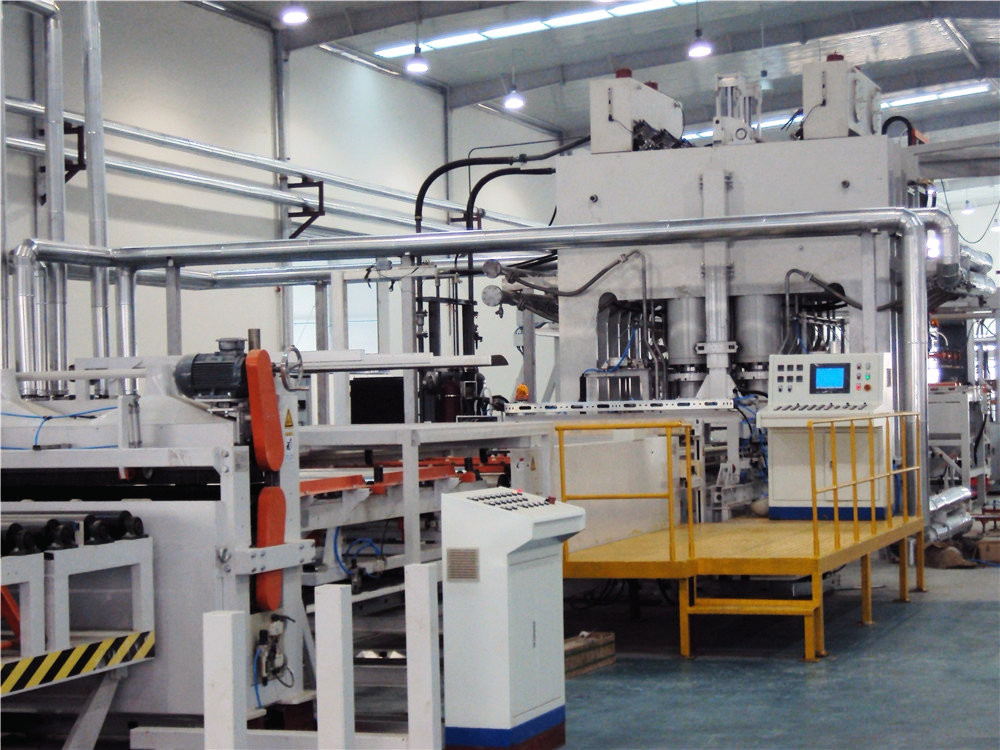

Efficient Short Cycle Lamination Laminating Hot Press Line

Application

Lamination of MDF, HDF, PB with impregnated paper for surface decoration and furniture production

Description

Assemble raw boards with impregnated paper and transported to hot press for short-cycle hot pressing to manufacture laminated boards.

Customer benefits

High output due to short cycle process

Low setup effort due to automatic configuration

Easy operation and maintenance

Technical features

High quality frame, oil cylinder and hot platen for uniform pressure and temperature distribution

Visualization system for electric control available

Semi-automatic and full -automatic configuration

Max. 150 pressing cycles per hour

Finished board with width 1.2m, 1.8m, 2.1m (4 ft, 6 ft, 7 ft)

Finished board with length 2.4m, 2.7m, 3.6m, 4.0m (8 ft, 9 ft, 12 ft, 14 ft)

Technical data:

Raw board with symmetrical density 600-900 kg/m3

Moisture content 5-7 %

Dimensions of raw board

Length 1,220, 1830, 2440, 3660 mm, can be customized

Width 1,220, 1830, 2440, 3660 mm, can be customized

Thickness 6~40 mm

Thickness tolerance after finishing sanding ±0.15 mm

Tolerance of board length, width and diagonal ±2 mm

Max weight of each sheet 110 kg

Height of raw board pile (max.) 1,100 mm

Height of finished board pile (max.) 1,100 mm

Weight of board pile (raw board, finished board) 3,000 kg

Board size;4*6';4*8';4*12'5*8';5*12';6*1';6*12' feet, can be customized

Main configuration:

Stack roller conveyor,

Lifting table with roller

Board pusher

Brushing machine

Centring device

Raw board transport and film suction bar

Lay-up belt

Loader and unloader

Short cycle press

Hydraulic unit for press

Edge trimming machine

Belt conveyor

Cooling station

Vacuum transport device

Electric control system

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!